The Role of CNC Machining in the Aerospace Industry

Precision and reliability are the cornerstones of aerospace manufacturing. The smallest error can have significant financial and safety consequences. CNC machining is the answer. It delivers the accuracy and consistency needed to create cutting-edge components.

From lightweight materials to complex geometries, CNC machining drives innovation that propels the aerospace industry forward. This guide explores the role of CNC machining in the aerospace industry in depth, shedding light on its capabilities and how it continues to shape the future of flight.

An Introduction to CNC Machining in Aerospace

Computer numerical control (CNC) machining serves as the foundation for creating countless aerospace components. It uses computer-controlled machines to remove material from workpieces with exceptional accuracy. This cutting-edge manufacturing technology supports aerospace development at every stage, from prototype creation to full-scale production.

The aerospace industry’s adoption of CNC machining stems from the technology’s ability to produce complex geometries that would be impossible or impractical to create using traditional manufacturing methods. It allows manufacturers to create parts with tolerances measured in thousandths of an inch while maintaining consistency across thousands of units.

Benefits of CNC Machining for Aerospace

Aerospace manufacturers depend on CNC machining for several reasons. Each benefit directly addresses the obstacles faced when manufacturing components for aircraft and spacecraft.

Superior Component Complexity

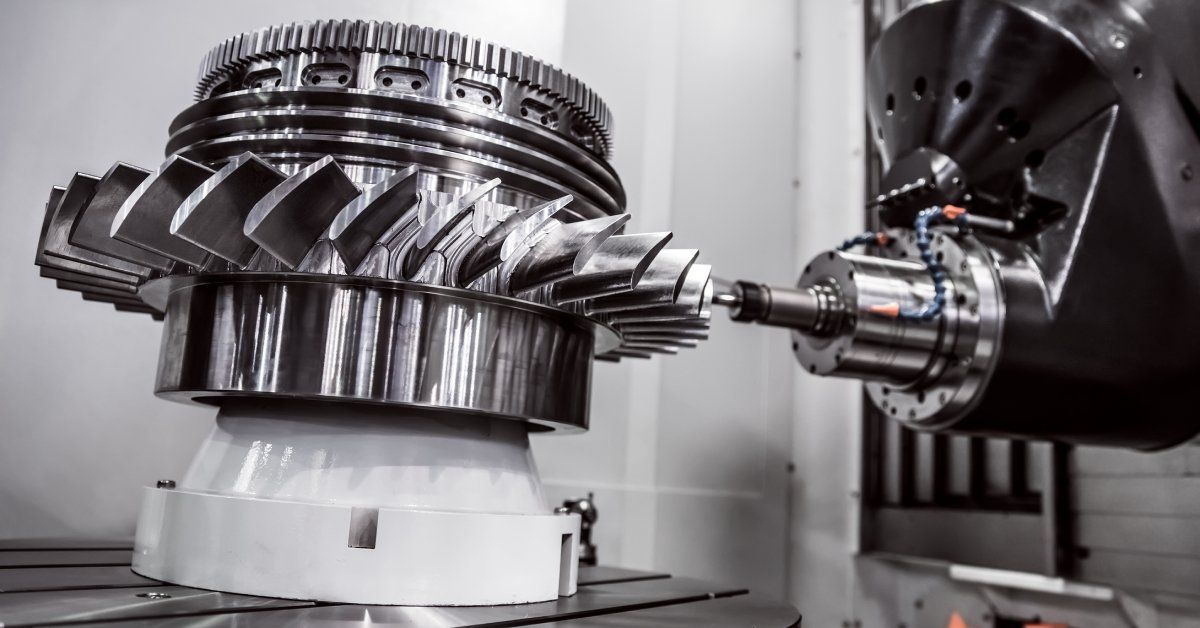

Modern aircraft contain thousands of intricate components with complex internal passages, curved surfaces, and precise mounting points. CNC machining is the ideal solution for producing these sophisticated geometries in a single setup due to its precision and versatility.

Multiaxial CNC machines can access multiple surfaces of a workpiece without repositioning. It decreases the risk of errors and maintains dimensional accuracy across the entire part.

Exceptional Precision

Aerospace components must meet extremely tight tolerances to ensure proper fit and function within large assemblies. The computer-controlled process eliminates human error while maintaining consistent quality standards.

CNC machines routinely achieve tolerances of ±0.001 inches or tighter, which is essential for components like engine and structural components. A high level of accuracy prevents issues, including vibration, premature wear, and catastrophic failure.

Enhanced Part Consistency

Consistency is particularly valuable for aerospace manufacturers who must produce replacement parts years after the original production run. CNC machining eliminates human error from the manufacturing process by relying on computer-controlled movements and cutting parameters. After validating a program, the machine will produce identical parts with uniform dimensions, surface finishes, and material properties, regardless of operator skill level.

Scalable Production Capabilities

CNC machining adapts well to both low-volume prototype production and high-volume manufacturing runs. These machines handle this transition smoothly without requiring significant changes to tooling or setup procedures.

The technology supports flexible manufacturing schedules that accommodate the aerospace industry’s complex supply chain requirements. Manufacturers can adjust production volumes based on demand while maintaining consistent quality and delivery schedules.

Reduced Manufacturing Costs

While CNC machining requires significant initial investment in equipment and programming, it decreases long-term manufacturing costs through improved efficiency and reduced waste. The precision of CNC machining minimizes material waste; this is particularly important when working with expensive aerospace materials like titanium.

CNC machining also diminishes labor costs by automating many manufacturing processes and allowing skilled machinists to oversee multiple machines simultaneously, increasing overall productivity.

Key Applications of CNC Machining in the Aerospace Industry

CNC machining serves multiple roles throughout the aerospace product lifecycle, from initial concept development to ongoing maintenance.

Rapid Prototyping

Research and development teams use prototype CNC machining services to quickly create functional prototypes. Engineers can test design concepts, evaluate performance, and make modifications without expensive tooling investments in a matter of days. The high-speed advantage helps aerospace companies bring innovative designs to market faster without compromising on thorough testing and validation.

Machined End-Use Components

The manufacturing process creates components that perform flawlessly under extreme temperatures, pressures, and stress loads. Common machined components in aerospace applications include:

- Turbine and compressor blades.

- Electrical connections.

- Engine casings and housings.

- Landing gear components.

- Hydraulic manifolds and valves.

- Wing spars and ribs.

- Oxygen generation systems.

- Interior cabin parts.

Replacement or Refurbished Components

CNC machining supports maintenance and repair operations by creating replacement parts for existing aircraft. Many aerospace components require periodic replacement due to wear or damage.

CNC machining can reproduce original specifications exactly. By restoring the aircraft’s function with a perfectly fitted component, the aircraft will have a longer service life and uphold safety standards.

Common Materials Used in the Aerospace Industry

Aerospace applications require materials that withstand extreme conditions while maintaining structural integrity. These materials must resist corrosion, handle temperature variations, and provide exceptional strength-to-weight ratios. CNC machining has the ability to produce various materials that the aerospace industry relies on.

Aluminum and Aluminum Alloys

Aluminum provides excellent strength-to-weight ratios that make it ideal for aerospace applications. The material machines easily and offers good corrosion resistance when properly treated. CNC machining creates precise aluminum components for structural applications, engine parts, and interior elements. Common aluminum alloys, like 6061 and 7075, deliver particular performance characteristics for a variety of aerospace requirements.

Titanium and Titanium Alloys

Titanium offers incredible strength and corrosion resistance for demanding aerospace applications. The material withstands extreme temperatures while maintaining structural integrity under stress.

Titanium components serve critical roles in engines, landing gear, and structural applications where performance cannot be compromised. Ti-6Al-4V is the most common titanium alloy in aerospace applications because it provides excellent mechanical properties across a wide temperature range.

High-Performance Plastics

Advanced plastic materials like PEEK, polycarbonate, and Ultem serve important roles in modern aircraft design. These materials offer weight savings, high-temperature resistance, and mechanical properties that metals cannot match. CNC machining creates precise plastic components for interior applications, electrical conduits, and decorative elements. These materials help reduce overall aircraft weight while maintaining necessary performance standards.

The Importance of Selecting Proper CNC Machining Partners

Aerospace manufacturers must choose machining partners with proven aerospace experience and essential quality certifications, such as AS9100, the internationally recognized quality management standard for the industry. Your selected partner should understand aerospace standards, maintain accurate documentation, and consistently deliver top-quality results.

Selecting the right partner ensures components comply with all regulatory requirements while maintaining competitive pricing and delivery schedules. Partnering with experienced aerospace machining specialists minimizes operational risks and guarantees the success of complex projects by leveraging their expertise, advanced technology, and industry knowledge.

Partner With Aerospace CNC Machining Experts

CNC machining continues to drive innovation and quality in the aerospace industry . The technology enables the creation of components that push the boundaries of performance while maintaining the safety standards essential for flight operations.

H&H Machine Service brings decades of aerospace machining experience to your projects. We combine advanced CNC technology with skilled craftsmanship to deliver components that meet your exact specifications. Contact H&H Machine Service today to discuss your aerospace machining requirements. Let our experience and expertise help bring your aerospace projects to successful completion.