Understanding Tolerances in CNC Machining

Accuracy and precision are hallmarks of CNC machining, and they are made possible by complex software and advanced equipment that produce custom components with minimal tolerances. Although tolerances are a widely discussed concept in CNC machining, they can be easy to overlook during the planning and prototyping phases.

Understanding tolerances in CNC machining is crucial for achieving the desired level of accuracy, avoiding production delays, and reducing manufacturing costs. In this blog, we’ll break down everything you need to know about machining tolerances, including their importance and how to determine them for your next project.

What Are Machining Tolerances?

Machining tolerances define the allowable difference between a part’s specified dimension and the actual measurement achieved during the manufacturing process. Absolute perfection is not possible, so tolerances are necessary to establish the acceptable limits within which a part’s dimensions can be.

Additionally, tolerances maintain compatibility and consistency between components, especially in assembly processes. They ensure that a part fits and performs as intended within its application, delivering precision while accounting for the realities of manufacturing variations.

How To Understand CNC Machining Tolerances

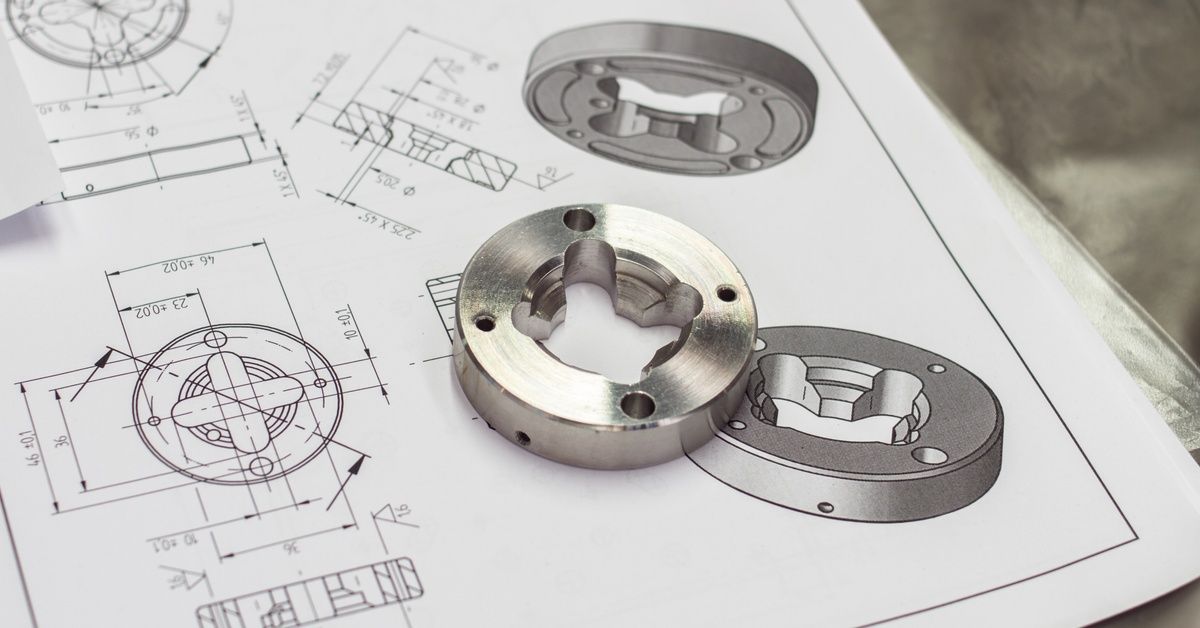

We write CNC machining tolerances in standardized formats to ensure clarity and consistency. They often include numerical values in measurements of millimeters (mm) alongside tolerance symbols (+, -, or ±) to indicate the acceptable range for each dimension. The technical drawings or CAD files shared with machine shops include these specifications. However, the format for expressing tolerances varies depending on the type of tolerance allowed for a specific component.

Types of CNC Machining Tolerances

We apply different types of tolerances to a part depending on its dimensional constraints and functional requirements. Below, we explore the common types of tolerances used in CNC machining.

Unilateral Tolerances

Unilateral tolerances permit variation in only one direction from the nominal value. For example, if a dimension is 50 mm with a tolerance of +0.2 mm, the actual measurement could range from 50 mm to 50.2 mm but never below 50 mm. Using the same example, unilateral tolerances may also be expressed by (+0.2/-0.00 mm). These tolerances are ideal for components requiring specific limits on one side. They ensure critical features remain intact while providing some flexibility in production.

Bilateral Tolerances

Bilateral tolerances allow variations in both directions, above and below the nominal dimension. For example, a specification of 50 mm ± 0.2 mm or +/- 0.2 mm means the part can measure between 49.8 mm and 50.2 mm. This flexibility is common in parts where minor deviations in either direction won’t impact performance or functionality, allowing manufacturers some level of adaptability.

Standard Tolerances

The standard tolerance in CNC machining refers to the widely used tolerance limit that machining shops set, usually when a tolerance is undefined. In many instances, the standard tolerance is approximately ±0.005 in. Industry standards, such as ISO or ANSI, are what typically define standard tolerances, and they ultimately depend on factors like material, machining process, and part size.

Limit Tolerances

Limit tolerances specify the maximum and minimum allowable dimensions for a part. Instead of a nominal size and deviation, only the range appears. For example, 49.8 mm to 50.2 mm is a limit tolerance. This approach simplifies the checking process, as inspectors just need to ensure the dimensions fall within these boundaries.

Geometric Dimensioning and Tolerancing (GD&T)

Geometric dimensioning and tolerancing (GD&T) adds a layer of specificity to tolerances by defining the allowable variation in the geometry of a part rather than just its dimensions. This method uses symbolic language to indicate acceptable tolerances for features like flatness, parallelism, and concentricity. This method is particularly useful for complex parts, ensuring they meet functional requirements in different positional or relational contexts.

The Importance of CNC Machining Tolerances

CNC machining tolerances play a critical role in the overall functionality and quality of a part. By defining acceptable manufacturing variances, tolerances ensure that components fit and interact correctly within assemblies. This is crucial in industries like aerospace, automotive, and medical devices, where even the slightest deviation can impact safety and performance.

Furthermore, tolerances contribute to cost efficiency. By establishing precise but realistic tolerances, manufacturers can avoid rework, minimize material waste, and reduce rejection rates. This translates into significant cost savings over time. Properly managed tolerances also enhance a company’s reputation by promoting high-quality products that meet or exceed client expectations.

What To Consider When Determining Tolerances

Choosing the correct tolerances for a project requires careful consideration of several factors. Below are the key elements to evaluate.

Material Selection

The material selection greatly influences the achievable tolerances. Heat stability, hardness, and abrasiveness are a few material properties that can affect what tolerances are attainable. For example, abrasive metals typically require larger tolerances. This is because they are harder to machine and may require multiple cutting tools to complete the process, and multiple tools are more likely to introduce dimension variability.

Surface Finishing

Surface finishes can alter a part’s dimensions subtly, affecting its tolerances. Processes like polishing, anodizing, or coating may add material to the part’s surface, which you must account for during machining. Always consider the post-machining processes necessary to achieve the desired finish when determining initial tolerances.

Machine Capabilities

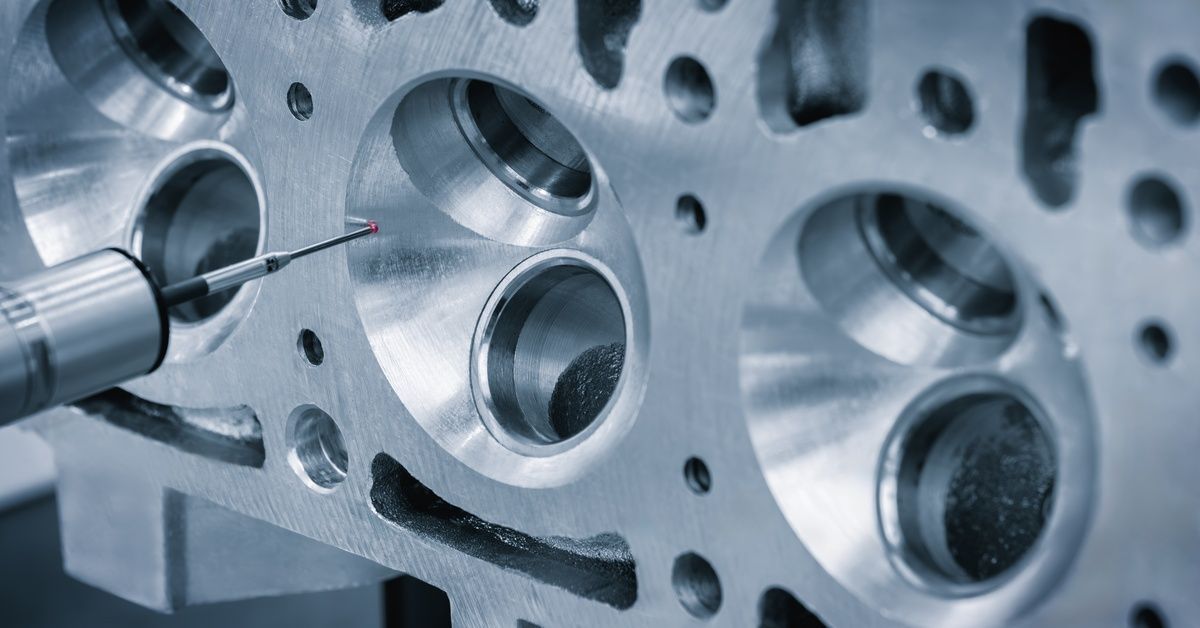

The type and capabilities of the available machines also shape your tolerance specifications. High-precision machines can achieve tolerances as tight as ±0.001 in. Additionally, factors such as machine calibration, maintenance, and operator skill play a role in maintaining consistent accuracy.

Project Cost

Tighter tolerances often require specialized tools and longer production times, which can increase project costs. For example, achieving extremely precise tolerances may involve multiple iterations of quality control checks, further adding to both time and expense. Balancing functional requirements with budget constraints is crucial to maintaining project feasibility while achieving quality outcomes.

Ensuring Precision in CNC Machining

Tolerances in CNC machining influence every aspect of the manufacturing process, from guaranteeing compatibility to maintaining cost efficiency. Understanding the different types of tolerances and their applications empowers manufacturers to make choices that align with their objectives while maintaining quality and functionality.

When precision matters, partnering with a trusted provider offering expertise in custom machine services is a smart move. Contact H&H Machine Service—located in Brenham, Texas—for custom machining to execute your tight tolerance projects with exceptional results. We have over 30 years of experience offering fabrication and manufacturing services to various high-stakes industries.